Introduction of full bonding technology for capacitive touch screen

Date:2019-08-13

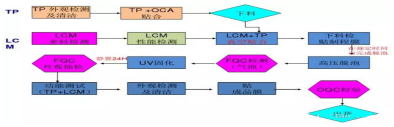

Capacitive touch screen is becoming more and more popular, using full fit technology. As we all know, full lamination is to use water glue or optical glue to smooth the panel and the touch screen to completely stick together in a seamless way. The touch screen full lamination technology eliminates the air between the screens, reduces the reflection between the display panel and the glass, makes the screen look more transparent, and increases the display effect of the screen. Now let's introduce the development of capacitive touch screen full fit technology

Capacitive touch screen full fit technology includes: in cell technology, on cell technology, OGS / tol technology, etc.

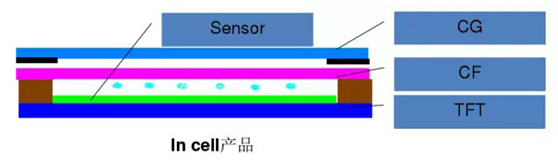

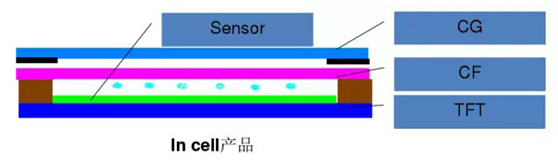

Capacitive touch screen in cell technology:

It refers to the technology that embeds the function of touch panel into LCD pixels, that is, the touch sensor function is embedded in the display screen. Therefore, the original three-layer protective glass touch screen + display screen becomes two-layer protective glass + display screen with touch function, which can make the screen lighter. This technology is mainly developed by panel manufacturers, and the threshold is relatively high.

In cell technology screen layer number: the in cell screen is composed of two layers of LCD layer bonded by surface glass (the touch screen is on the LCD layer).

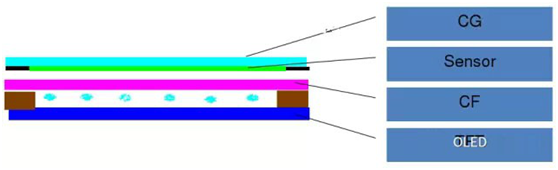

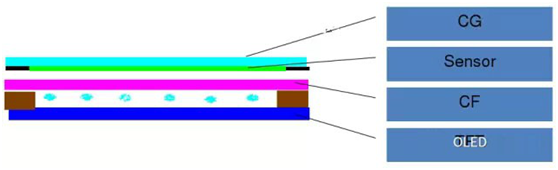

Capacitive touch screen on cell technology:

On cell is a method to embed the touch screen between the color filter substrate and the polarizer of the display screen. That is to say, the touch sensor is equipped on the LCD panel, which is much less difficult than the n-cell technology.

On cell is mostly used in Samsung AMOLED panel products, but it can't overcome the problems of thinness and uneven color when touching.

On cell technology screen layer: the touch screen and LCD layer are bonded by the surface glass, a total of 3 layers.

Touch screen OGS / tol Technology:

OGS technology is to integrate the touch screen with the protective glass. The conductive layer is plated on the inner side of the protective glass, and the coating and lithography are directly carried out on the protective glass. Because one piece of glass and one-time bonding are saved, the touch screen can be thinner and the cost is lower.

TOL refers to the OGS chip manufacturing process, that is, after the white glass is toughened, the BM and functional electrode are made. The strength of its products is higher than that of OGS, but because of the low efficiency of the process, the cost is also higher. Many domestic mobile phone brands have adopted OGS technology. However, OGS is still faced with the problems of strength and processing cost, both of which need secondary strengthening to increase the strength.

OGS technology screen layer: by OGS layer bonding LCD layer, a total of 2 layers.

Touch screen other traditional full paste technology

GG, PG, GF, g1f, GF2, GFF and so on all need to be bonded twice, the thickness is relatively thick, and the yield is not high.

Screen permeability: OGS is the best, followed by in cell and on cell, and GFF is the worst.

Thinness: in cell is the lightest and thinnest, which is one of the reasons why I phone and P7 mobile phones can be made thinner, OGS and on cell are the second, and GFF is the worst.

Screen intensity: GFF > on cell > OGS > in cell.

Touch effect: in a strict sense, the touch sensitivity of OGS is better than that of on cell / in cell, but touch is also related to the underlying optimization of mobile phone system. For example, the touch experience of I phone with in cell is much better than that of many Android phones.

Cost and technical difficulty: in cell / on cell has higher difficulty and cost, followed by OGS / tol. GFF has the lowest cost and technical difficulty, so it is mostly used in 1000 yuan computers.