Hangzhou Xuhong Technology Co.,Ltd

EN

中文

1、Problem description

Defective serial number | Product model | Product code | Adverse customer complaints | Our company's re judgment phenomenon | Adverse causes | Remarks |

1# | PC070IA15-B27-L800 | 231121TTS2700229 | Flower screen | Backlit, display black screen | ITO burning | VDD |

2、Root Cause

1. Confirm the customer return defective module cycle of 23 years and November (as shown in the figure);

2. The defective module returned by the customer is confirmed to have a bright backlight when lit, and the FOG is not displayed on the black screen (as shown in the picture);

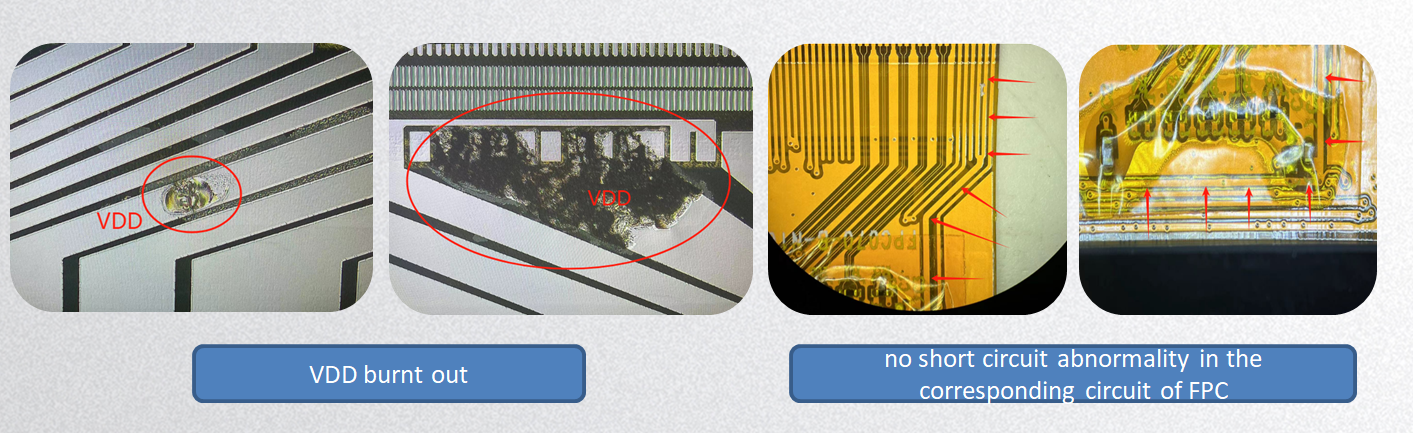

3. Disassembling the module and conducting a microscopic inspection under OM, it was found that there was ITO electrical corrosion and burning phenomenon. Confirm that the burnt out position corresponds to the VDD circuit (as shown in the figure);

4. Check the corresponding circuit of FPC to confirm that there is no incoming short circuit phenomenon, and eliminate the short circuit problem of the module product itself (as shown in the figure).

5. The product has gone through 5 inspection and testing processes (FOG testing - module assembly testing - module shipment inspection testing - client full inspection - touch full adhesion full inspection) and is all OK. However, there is a VDD burning defect at the end customer;

6. Overall:

1. It is speculated that the cause of VDD burning is due to the terminal customer's incorrect insertion and removal of the PIN, which caused a short circuit during power on and resulted in poor VDD burning.

2. The customer's motherboard VDD may have excessive peak instantaneous current (specific measurement and analysis of the customer's motherboard are required).

3、PERMANENT ACTION

Targeting Flower Screen - VDD Burnout

a. Hot swapping (PIN insertion with power) operations are prohibited throughout the entire production testing process.

b. When assembling and inserting a PIN on the client side, ensure that there is no misalignment before powering it on for testing.

c. It is necessary to investigate whether there may be peaks or excessive instantaneous current in the VDD of the customer's motherboard (specific measurement and analysis of the customer's motherboard are required).

4、Verification of the effectiveness

1. Continuously following up on customer feedback on abnormal issues

2. Continuously monitor the production line and customer's functional defects, and promptly analyze the causes of any defects.