Hangzhou Xuhong Technology Co.,Ltd

EN

中文

Report on black screen feedback from the 8-inch high-definition LCD screen of INNOLUX

D1(Problem Description)

The customer reported that there were defects in the LCD screen, and a total of 4PCS of defective products were returned.

A total of 100PCS were shipped after re evaluation Two of them were misjudged, and the other two had a black screen defect

rate of 2%.

Screen 1 customer feedback black screen

D2 Containment Action Taken

D2 Emergency Action Taken

1、All products in stock were tested and no such phenomenon was found.

2、Regarding the traceability of this product, another customer of this batch also reported individual black screen phenomena.

D3Analysis and Identification of Root Cause

1. The returned defective products have been tested and the results are as follows

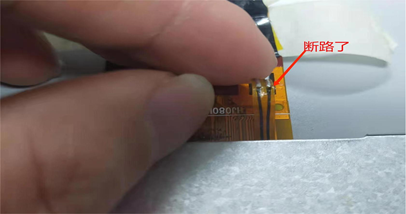

Screen 1: Black screen, actual measurement shows that the screen is indeed black. After re welding the backlight, the LCD screen displayed normally.

Screen 2: Black screen, the phenomenon is also black screen. After re welding the backlight, the display is normal.

After careful analysis, it was found that the cause of the defect was due to the backlight welding personnel pursuing speed too much when welding the backlight wire,Resulting in virtual soldering during individual backlight soldering, causing the FPC soldering position to disconnect after customer installation, resulting in a black screen.

D4 Corrective Action Taken&Verification

1. Train welding personnel in the factory and supervise the improvement of quality awareness

D5 Preventive Action Taken&Verification

1. In the quality inspection stage, add pulling and pulling cable testing actions to control the detection of welding defects within the factory

D6 Standardization

Add the process of pulling and wiring in the standard operating procedures for the testing process.

D7 Validation of Long term Effectiveness

1. Continuously follow up

D8 retention issue

TFT LCD:https://www.auo-lcd.com/