LCD display technology -Introduction to CF substrate

Date:2023-08-23

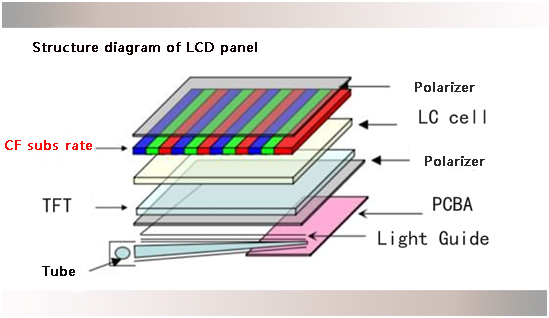

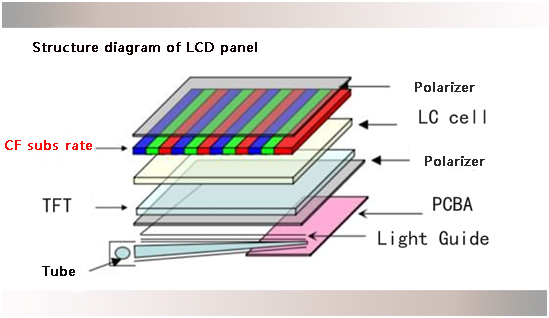

The CF substrate of the TFT LCD is a key material for realizing TFT LCD

color display, which occupies the highest cost in the display screen. In

addition to affecting the color, the CF substrate also affects the optical

characteristics of TFT LCD's brightness and contrast. Below we briefly introduce

the material composition and product characteristics of the CF substrate.

1. The composition structure of the CF substrate

The main materials of the CF substrates include glass substrate, black

matrix BM, color layer RGB, protective layer OC, ITO conductive film, column

-shaped Spacer, etc. Different display modes, the composition structure of the

CF substrate will be slightly different.

1. Black matrix BM: Basic function is to shake light, improve the

contrast,avoid connected color layer mixing, reduce external light reflection,

and prevent external light from irradiating the A-SI layer to increase the

leakage current. Using BM can effectively cover the light leakage between the

pixels. To obtain a good shielding effect, it must be high -shading

concentration. The shading concentration is represented by OD value. The larger

the OD value, the better, which generally requires above 3.0. The resin BM is

basically used in the project, because the cost of resin BM is low and the

reflectance is low, and the phenomenon of reflex light or redness will not

occur. In addition to increasing the contrast of TFT LCD, in addition to

increasing the OD value of BM, it is necessary to strengthen the size accuracy

management to prevent leakage caused by the bonding deviation.

2. RGB color layer material: Most of the TFT LCD uses pixel segmentation

method to achieve color display, and the CF substrate forms RGB triple color

light. From the front of the CF substrate, the RGB color layer arranges can be

divided into strip arrangement, dot -shaped arrangement, triangular arrangement,

mosaic arrangement. Bar-shaped and dotted arrangements are generally used for

large -sized, high -fine TFT LCD products. Triangular and mosaic arrangements

are generally used for small -sized, low -precision TFT LCD products. The color

and transmission are the two optical characteristics of the CF substrate, mainly

depending on the RGB color layer material.

3. Protective layer OC, ITO conductive membrane, cylindrical spacer : The

role of the OC layer is to protect the RGB color layer while achieving the flat

surface of the CF surface. For the TN display mode and VA display mode, because

the RGB color layer will have ITO facial electrode coverage protection, it may

not require OC layer. IPS display mode does not have ITO facial electrode

coverage protection, and the OC protective layer is required. ITO conductive

film is a transparent film for conductive electricity. Because it is on the path

of light, its light transmitted rate must be high. The cylindrical spacer spacer

is to maintain cell gap uniformity , and the main component is UV hardening

acrylic resin.

2. The performance requirements of the CF substrate

The performance requirements of the CF substrate are: high transmission

rate, high color purity, high contrast, high reliability, low reflectivity and

other aspects.

1. High transmission: It is the need for energy and cost saving ,which is

decided by the opening rate of the pixel of R, G, and B, that is, the ratio of

the opening area defined by the opening size of BM to the overall area of the

child pixel.

2. High -color purity: The color coordinate of RGB directly determines the

color range that the TFT LCD can display. The indicator of the TFT LCD color

performance is the color domain. The higher the color purity and the stronger

the color display ability. TFT LCD products generally use NTSC -based color

gale.

3. High contrast: The OD value of the BM layer has a great impact on the

contrast of the CF substrate, especially the OD value of the BM layer around the

display screen. From the perspective of OD values, the thicker the BM layer, the

better.

4. High reliability: The reliability items of the CF substrate include heat

resistance, drug resistance, optical resistance, OC attachment, and ITO

stability. In terms of heat resistance, under the formation temperature of ITO

surface electrode formation, the color of RGB and BM will not change, nor the

phenomenon of membrane layer peeling. In terms of drug resistance, the OC

layers, ITO layers, and PS layers formed after the RGB color layer must be

treated with medicinal solution, washing fluid, etc., and the impact of non

-crossing must be maintained. In terms of light resistance, it is required to

avoid discoloration or fading CF substrate materials under the light of the

backlight source, or the external ambient light. In terms of OC attachment, it

is necessary to ensure that the OC layer, the RGB color layer, and the BM layer

have good attachment, but also to ensure that of the OC layer and the ITO layer

are good. In terms of ITO stability, it is necessary to ensure that in the

abnormal environment, the ITO layer also has a high pass rate and low

resistance.

5. Low reflectance: If TFT LCD is not used in dark environments, there will

be a reflection phenomenon of display. For the CF substrate, an important factor

affecting the reflection is the reflectivity of BM. Use black resin as a BM

layer with the lowest reflectivity.