LCD display theory -PCB substrate

Date:2023-08-30

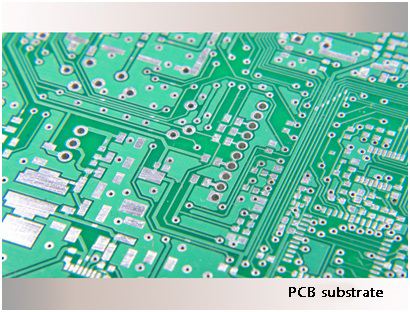

In the TFT LCD, various electrical components are connected to each other,

and the PCB substrate of the circuit board is used as a medium and carrier. The

PCB substrate is made of material that is insulated and not easy to bend, and

the fine line material that can be seen on the surface is copper foil. These

copper foil circuits are used to provide circuit connections of PCB upper

components.

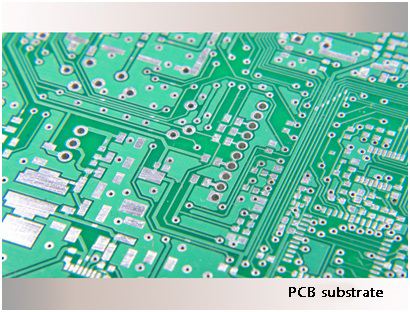

TFT LCD uses SMT technology with PCB substrates. Welding is on the same

aspect as components. The components used are small, which can increase the

utilization rate of the PCB area. The corresponding symbols will be marked on

the side of various components on the PCB substrate, for the corresponding

functions. For example, the resistance r function is to reduce the voltage and

control the current; the capacitance C is a bypass component for input power and

various components; the inductance L is the energy to generate energy in the

DC/DC circuit, which turns the input voltage into a high voltage. Crystal tube Q

is used as switch and is used for amplification of current and voltage.

In the small and medium -sized TFT LCD, the FPC of soft printing circuit

boards is commonly used for the connection between the display screen and the

PCB substrate, and between the TFT LCD and the host. Compared with the PCB hard

board, the FPC has light weight, small volume, and good heat dissipation. It can

be bent freely and folded. It can be arbitrarily moved and expanded according to

the spatial layout requirements to reach the integrated wire connection of

component assembly. The disadvantage of FPC is that the mechanical strength is

small, the possibility of heavy processing is low, it is difficult to check, it

is easy to produce wrinkle scars, high costs.

AUO LCD:https://www.auo-lcd.com/products/auo-lcd-screen/