Hangzhou Xuhong Technology Co.,Ltd

EN

中文

Nowadays LCD screens are ubiquitous, and capacitive touch screens are the most widely used. In order to realize touch function, the display product must be equipped with a capacitive touch module, which is bonded to the LCD screen to realize the touch control. It is important for customers to determine the solution for capacitive touch module customization. In the capacitive touch module, the most important component is the top cover lens. We can customize the cover lens to meet the needs of touch display. Below we will introduce in detail the cover lens customization of capacitive touch screens.

1、The introduction of glass cover lens.

The raw material of cover lens for capacitive touch screen is original glass, also named mother glass. As the protective glass of capacitive touch screen, it plays the role of window protective screen. Glass cover lens is widely used in smart phones, tablet computers, smart wear, automotive touch screen, smart home appliances and other LCD products with touch function. Its basic functions are anti-fall, anti-scratch, pressure resistance, high temperature resistance, protection of LCD, decorating and beautifying product surface.

2、 Customization of cover lens

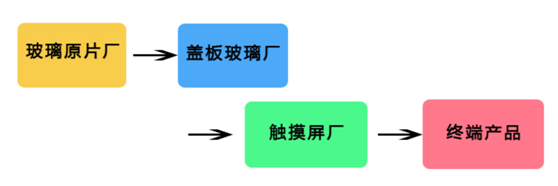

The customization solution of the glass cover lens is a mature industrial chain. The original glass sheets are firstly processed by cover lens factories, then processed by touch screen factories, finally supplied to LCD screen manufacturers.

First, we introduce the original glass factories which are in the upstream of the industrial chain. The original glass factories supply the original glass sheets, and the representative factories are Asahi Glass, KangNing, Asahi Hong Optoelectronics, South glass A, etc. According to chemical composition, the glass can be divided into Sodium-calcium silicate glass, sodium-aluminosilicate glass and lithium aluminosilicate glass. The higher the aluminum content, the greater the hardness and mechanical strength of the glass, but at the same time, the screen is more likely to break. Therefore, high aluminum glass requires higher technological level. The main production processes are 2 kinds: overflow process and float process. The overflow process adopts the production method without contacting other interfaces, without polishing treatment, with the characteristics of high strength and high yield, it is suitable for the production of mobile phone screen and other products with high requirements. The float process technology is also quite mature with higher production capacity and lower cost, which is suitable for the production of large-size glass.

Secondly, we will introduce the cover lens factories, which are the downstream of the original glass factories. The main technology of the cover lens factory is chemical strengthening. The technology of domestic cover lens factories has been very mature, representative companied are Lens technology, Bern. The chemical strengthening process of glass cover lens is divided into one-step strengthening and two-step strengthening. Chemical strengthening process is the core process of glass cover lens, there are two indexes: compressive stress CS and ion exchange layer depth DOL. The improvement of CS helps to prevent and delay the extension of micro-cracks on the glass surface to the inside, so as to improve the mechanical ability of the glass against bending and scratching. DOL improves the anti-scratch and anti-beating ability of the product surface, prevents micro-cracks from invading the stress layer, and forms an effective protective barrier. The glass cover lens of the capacitive touch screen is strengthened by one step and two steps, the surface compressive stress CS is not less than 700MPa, and the ion exchange depth DOL value is higher than 100gm, so that the anti-fall and anti-destruction ability of the whole display product is effectively guaranteed.

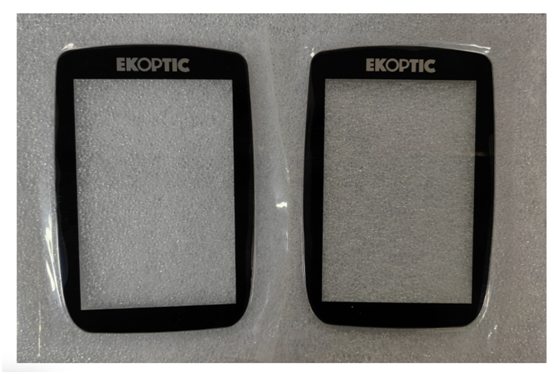

Now, let's talk about the touch screen factories, which are the downstream of the cover lens factories. The touch screen factories are mainly responsible for the production and installation of touch control modules. The main technology is optical bonding technology, which is used to fit the capacitive touch module and finally cover the glass cover lens. Optical bonding is the core technology of a touch screen factory, Domestic touch screen factories have very mature technologies, such as BOE, TPK and so on. According to the customer's demand, we can add screen printing on the back of the cover lens. We know that the glass cover lens is the top layer of the whole product. We can customize a cover lens that is larger than the display active area, and add screen printing in the black border outside the display area, customize the product LOGO, beautifying the product and increasing the visibility of the product.

Through the above, we must have a preliminary understanding of the customization of cover lens for capacitive touch screen. At present, domestic glass manufacturers have been catching up, constantly breaking through technology, and gradually narrowing the distance with the international leading enterprises.