Hangzhou Xuhong Technology Co.,Ltd

EN

中文

AF ---- Anti-Finger Print, general SiO2+AF material (DON, M4, Dow comming AF material), generally use vacuum evaporation coating method.

Anti -fingerprint glass treatment (also known as pollution -proof glass treatment) reduces the ability of the cover to block the finger oil. AF treatment is usually carried out by vacuum deposition or liquid chemistry, which will produce oil sparse surface coating. Because this layer is the chemical modification of the glass surface, it is very durable compared to the AF spray coating film in the after -sales market.

The principle of AF glass: anti -staining and anti -fingerprint glass is based on the principle of lotus leaf. A layer of nanochemical materials are coated on the surface of the glass to reduce the tension of the glass surface and reduce the area of contact with the surface of the dust and glass by 90%. Therefore, it has strong hydrophobic, oil -resistant and anti -fingerprint capabilities and the viewing glass panel will maintain a smooth and beautiful effect for a long time. It must be noted that AF glass treatment cannot reach completely fingerprints resistance. They only make finger oil form beads on the surface,less noticeable and easier to remove from the screen.

Another advantage of AF coating is to deal with the touch feeling or user perception on the surface. Because the surface is smooth, fingers will be easier to slide compared to unprocessed surfaces. The surface of the unprocessed cover lens may cause the user's fingers to stick, skip, and feel like being dragged, and even drawing a single line on the screen becomes difficult, making it a dotted line.

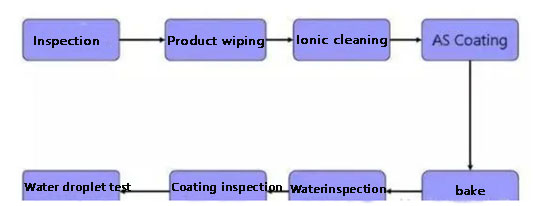

Process process of anti -fingerprint treatment

1. Pre -treatment: Use weak alkaline cleaning agents or solvents to remove stains such as oil division and moisture on the surface of the substrate and the effect of cleaning through ultrasound is better;

2. Plated AF medicinal liquid on the product surface into a film;

3. Baking: After spraying, take out the glass and put it in the oven (120 degrees, 30 minutes). The adjustment of the specific requirements and the situation of the product to the best;

4. Clean: After the product is cleaned, the finished product is packaged;

Features and application areas

AF coating product characteristics:

1. Anti -pollution: Prevent fingerprints and oil pollution is not easy to adhere and easily erase;

2. Scratch: smooth surface, comfortable, not easy to scrape;

3. Membrane layer thin: excellent optical performance, without changing the original texture;

4. wear resistance: have true abrasion resistance

AF coating product application field: mobile phone, tablet, TV, LED and other glass display.