Hangzhou Xuhong Technology Co.,Ltd

EN

中文

What is AG glass?

Anti-Glare glass, referred to as AG glass, is a glass that is specially treated on the glass surface. The principle is to processes the single -side or double -sides of high -quality glass, so that it has a lower reflection ratio compared with ordinary glass, thereby reducing the disturbance of the environmental light, increasing the clarity of the picture, reducing the screen reflector, making the image more Clear and realistic, let the viewers enjoy better visual effects.

The advantages of using AG glass:

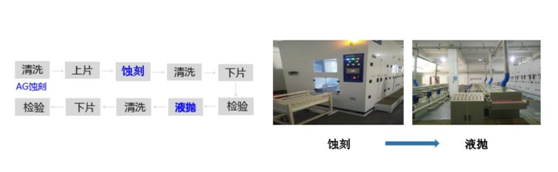

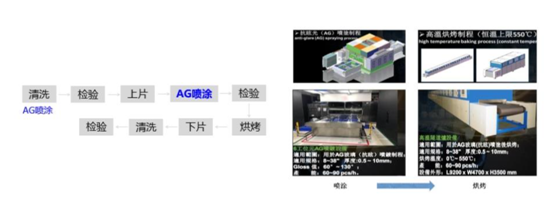

AG glass processing process:

Common AG processes are mainly divided into: chemical etching AG, spray AG, coating AG, sandblast AG, and film AG. The following mainly introduces coating AG, sprayed AG, and chemical etching AG process.

1. AG coating (anti -glare coating) is a atomized coating technology. The AG anti -glare film is a type of polarizing tablet. By performing microfinance on the surface of the polarizer, it is necessary to prevent the light from entering the eyes, thereby effectively reducing glare and reflection. Originally applied to a car rearview mirror. The processing of coating AG determines that its hardness value is difficult to change. The coating AG scratches after a period of use, and the handwriting touch is not far from the tactile touch on the paper. Therefore, it is limited to its application range and basically only applied to the rear -view mirror. A small amount is used on TV screen glass and navigation instruments glass. As the requirements of the AG glass are getting higher and higher, the coating AG gradually fades out of the market.

2. Spraying AG technology is to form a layer of uniformly dispersed nano -grade silicon particles suspension on the glass surface by spraying equipment which is attached to the glass surface on the glass surface after heat treatment . Its advantage is that this processing process is convenient and fast, and the production efficiency is high. It can easily process high -quality products with different luster and mist. The disadvantage is that the granularity of the spray AG is still a bit unsatisfactory. It is difficult to adjust the gloss and roughness of the AG glass to a large extent. Due to the environment and use factors, the AG layer peeling and the friction resistance of the AG surface decline.

3. Chemical etching AG, with hydrofluoric acid, fuses the silicon oxygen on the glass surface layer, and obtains a glossy surface or no glossy surface depending on the degree of solubility of residual salt. It is characterized by turning the original glass reflective surface into a matte manner. It can cause the reflector to blur, prevent the reflectiveness beyond the glare, and reduce the light and shadow. Anti -glare products have strong anti -corrosion and injury. Solve the reflection and glare of the electronic screen and image screen in the ambient light. The etching AG is a chemical etching. After the AG is treated, it is still the glass surface. So the product life is equivalent to the general reinforced glass. The uniform granules cannot be achieved by the first two processes.