Hangzhou Xuhong Technology Co.,Ltd

EN

中文

More and more TFT LCD screens are being used outdoors, such as outdoor billboards, bus stop signs, vending machines, outdoor handheld devices, as well as car touch screens, ship displays, and so on. The outdoor environment is usually under strong light, and the light is relatively strong. Ordinary display screens may not be able to see the picture clearly. This is because outdoor light forms reflections on the surface of the screen. If the brightness of the display screen is lower than the brightness of the reflected light, the reflected light will mask the color of the screen light, causing us to not see the picture clearly and reducing the readability of the screen. How to improve the visibility of TFT LCD screens in direct outdoor lighting and achieve readability under sunlight? Below, we will share several solutions.

What are the key elements for achieving readability of TFT LCD under sunlight?

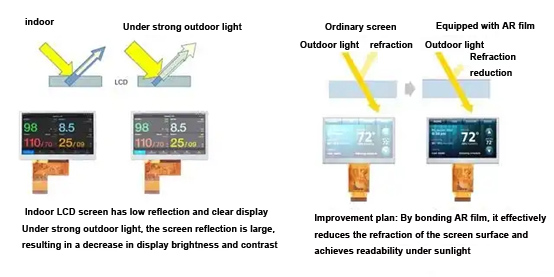

Before we introduce the solution, let's first understand the key elements for implementing TFT LCD readability under sunlight. Our visual perception of things is usually based on brightness and contrast as a reference for clarity. Therefore, the brightness and contrast of the display screen are key to the clarity of the image. The higher the contrast, the better the clarity and color reproduction of the screen, and the higher the viewing experience for people. The fundamental reason why LCD screens are not clear when viewed outdoors, as we mentioned earlier, is the refraction of outdoor light. So it can be inferred that only by finding a way to make the brightness of the LCD screen exceed the refraction of the screen surface, can the screen truly achieve readability under sunlight. We can achieve this goal through two key elements: enhancing the brightness of the LCD screen itself and reducing the reflected light on the screen.

Is there a solution for LCD screens to be readable under sunlight?

Firstly, let's talk about enhancing the brightness of TFT LCD screens:

1. Brightening of LED backlight source

Under strong outdoor illumination, the brightness of the ambient light source is approximately 6000cd/m2 or higher. Generally speaking, the refractive index of the surface of TFT LCD screens is about 10%, which means that about 600cd/m2 of refracted light will be formed. Therefore, as long as we use a high brightness LED backlight source to increase the brightness of the LCD screen to around 600 to 1000 Nits, surpassing the refraction of ambient light, we can achieve readability of the LCD screen under sunlight. For example, outdoor handheld devices such as drone remote controllers and infrared thermometers that we commonly use have screen brightness typically ranging from 800 to 1000 Nits.

2. Adopting semi reflective and semi transparent technology

The semi reflective and semi transparent LCD screen adopts a display technology that combines reflection and transmission. It can be seen in outdoor sunlight like a reflective LCD, and can display normally in indoor environments like a transmissive LCD. The main structural difference is the addition of a reflective layer between the LCD screen and the backlight. In outdoor lighting conditions, the light sensor of the semi reflective and semi transparent screen controls the backlight to adjust the brightness of its own backlight to a very low level. Through the reflective layer, the ambient light is converted into the backlight source of the LCD screen, thereby increasing the brightness and contrast of the screen. The stronger the outdoor light, the higher the converted brightness, making the LCD screen readable under sunlight.

Next, we will introduce reducing the reflected light of LCD screens:

Reduce reflection on the surface of LCD screens - AR film

Firstly, let's understand what light reflection is. When light is at the boundary between two different media, a portion of the light will reflect back from this boundary, which is called light reflection. On the surface of the screen, reflection occurs between the air and the glass surface. Therefore, this is directly related to significantly reducing the reflected light of LCD screens by adding AR films on the screen surface. AR film is an anti reflection film and anti glare film, and its bonding requires certain technology and processes. The combination of AR film and tempered glass is an excellent display solution, which enhances the surface strength of the screen while preventing reflection and achieving readability under sunlight.

AR film achieves readability of LCD screen under sunlight

2. Reduce internal reflection of the screen - In capacitive touch screen products, in addition to the reflection on the LCD surface, the air gap between the touch module and the LCD screen is also an important source of reflection through optical bonding technology. The most effective solution is to use optical bonding technology to eliminate this part of the air gap. Due to the optical binding, the air gap between the touch module and the LCD screen is completely filled, and the refractive index of the transparent optical adhesive is almost equal to that of the screen film, thus eliminating the reflection between different media. Moreover, optical bonding not only achieves readability under sunlight, but also enhances the overall strength of capacitive touch screens, reducing the risk of water vapor entering, making it the best screen bonding process.

This article elaborates on the solution for TFT LCD screens to achieve readability under sunlight from two aspects: enhancing the brightness of the LCD screen itself and reducing the reflected light on the screen. With the continuous development of LCD screen technology, there will be more and better solutions for reading under sunlight, which can solve the problem of screen clarity in outdoor environments while better protecting our eyes.