Hangzhou Xuhong Technology Co.,Ltd

EN

中文

Capacitive touch screens are now widely used in the industrial field, and their touch technology is constantly being updated and upgraded. So what are the mainstream capacitor screen process structures currently available?

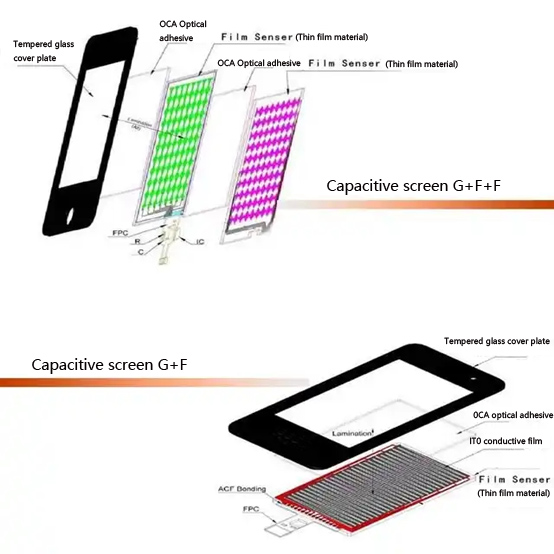

1.G+F process structure of capacitive screen

The capacitive screen with G+F structure has a first layer of surface tempered glass and an additional layer of FILM

film material. That is, glass cover plate+OCA+Film Senser. Glass cover plate: It plays a role in protecting the screen

and optimizing the surface texture. Generally, tempered glass material with high strength, hardness, and good

transparency is selected. OCA: It is a solid-state optical adhesive with good viscosity and strong light transmittance,

used for bonding between glass cover plates and Film Sensers. Film Senser: A sensor made of film material, which is

the signal function layer of a capacitive screen, transmitting touch signals and enabling touch functionality. Scope of

application of this structure: Suitable for products under 3.5 inches, low-cost solution.

2. G+F+F process structure of capacitive screen

The capacitive screen with G+F+F process structure also has a surface tempered glass as the first layer, with

the difference being the addition of 2 layers of FILM film material. The difference from the G+F structure is the

addition of an extra layer of Film Senser. G+F+F can achieve multi touch, and the screen is thinner, with a higher

cost than G+F.

3.G+G process structure of capacitive screen

The capacitive screen with G+G process structure, namely GLASS+GLASS, has a first layer of surface tempered

glass and an additional layer of glass material Senser. The biggest difference between him and the G+F structure

is the use of a glass material for the Senser. The characteristics of G+G capacitive screens are: hard and wear-resistant,

corrosion-resistant, high light transmittance, smooth handling, and good reliability. Due to the fact that the surface

cover is made of tempered glass, its surface is very hard, with a hardness of over 8H, making it very effective in

preventing scratches.

4、 G+P process structure of capacitive screen

The capacitive screen with G+P process structure has a first layer of surface tempered glass and an additional touch

layer made of PC material. The characteristics of G+P capacitive type are low cost and simple process. Disadvantages:

Not wear-resistant, not corrosion-resistant, poor light transmittance, slow operation, poor reliability. The above are

the most common capacitor screen process structures currently available on the market. In fact, each structure has its

own advantages and disadvantages, and users need to choose the suitable capacitive screen product based on their

own cost and application field.