Hangzhou Xuhong Technology Co.,Ltd

EN

中文

There are generally two design methods for designing human-computer interaction interfaces for LCD displays:

Option 1: The LCD display module only exposes the display area, with plastic or metal frames outside the window for protection;

Option 2: Stick a glass cover plate on the surface of the LCD display screen, apply adhesive on the back of the glass cover plate, and install the cover plate onto the chassis to make it look more beautiful and overall.

Here we will focus on the second solution: adding a piece of glass on the surface of the LCM (LCD display module), which can be directly attached to the LCM surface or equipped with a touch sensor. We can do screen printing outside the display area of the cover glass, add your brand logo here, or perform some surface treatments on the cover glass, such as AG, AR, AF, etc. Meet the needs of various scenarios.

Here we need to provide some explanations and clarifications on AG, AR, and AF, which are all related to the surface treatment of glass cover plates: Anti reflection (AR) - reduces the reflection on the display surface by applying a specific thickness of coating on the glass cover surface. Anti glare (AG) - eliminates bright glare on the display screen surface by creating a rough surface on the protective cover. Anti fingerprint (AF) - prevents fingerprints and stains from appearing on the surface of the display screen by applying a treatment that reduces the oil retention ability of the glass cover.

Regarding the thickness of the glass cover plate:

Tempered cover glass can also be made in different thicknesses. We have 0.55mm, 0.7mm, 1.1mm, 1.8mm, 2.0mm, 3.0mm to choose from, and 4mm, 6mm, or even thicker. Of course, the quality of these two thicknesses of glass may be slightly inferior and they do not belong to optical glass.

Thickness of glass cover plate

Another issue has arisen here, where glass with a thickness of 3mm or more requires higher driving capabilities for touch

chips due to the need for touch functionality. We use touch solutions such as Iiltek, EETI, Microchip, etc. to achieve touch

on thick cover plates.

Regarding the shape of the glass cover plate:

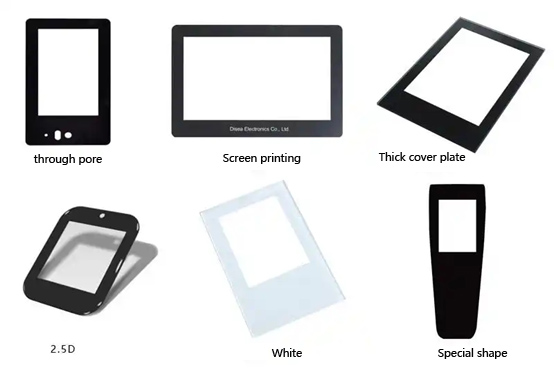

Because the cover glass is actually the first layer of medium that directly contacts the user, it must be finely crafted and flawless. It can also have various shapes that perfectly match your overall design. It can be irregular, have through holes, silk screen holes, 2.5D edge effects, have steps, and so on.

Glass cover screen printing, 2.5D

AUO LCD:https://www.auo-lcd.com/products/auo-lcd-screen/