Working principle and application of resistive touch screen

Date:2019-04-26

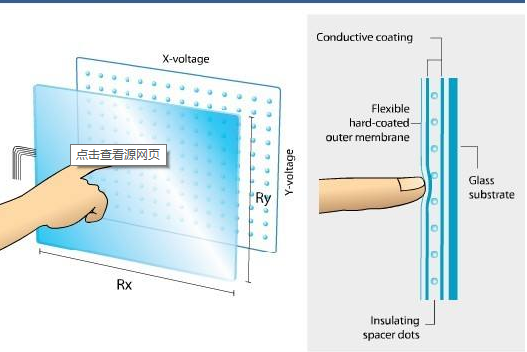

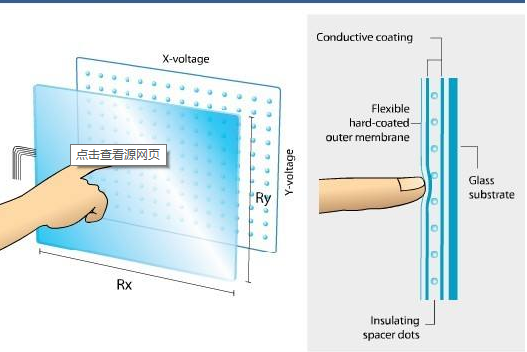

Resistive touch screen is a kind of sensor, which converts the physical position of touch points (x, y) in rectangular area into voltage representing X and Y coordinates. Many LCD modules use resistive touch screen, which can use four wire, five wire, seven wire or eight wire to generate screen bias voltage and read back the voltage of touch point.

Resistive touch screen is controlled by pressure sensing. The main part of the resistive touch screen is a resistive film screen which is very compatible with the surface of the display. This is a multi-layer composite film. It takes a layer of glass or hard plastic plate as the base layer. The surface is coated with a layer of transparent metal oxide conductive layer, and then covered with a layer of plastic layer with external surface hardening treatment and smooth anti friction. Its internal surface is also coated with a layer of coating There are many small transparent isolation points between them to separate and insulate the two conductive layers. When the finger touches the screen, the two conductive layers have contact at the touch point, the resistance changes, and the signals are generated in X and Y directions, and then sent to the touch screen controller. The controller detects the contact and calculates the position, and then operates according to the mode of simulated mouse. This is the most basic principle of resistive touch screen technology. The key of resistive touch screen is material technology, commonly used transparent conductive.

The electrical coating materials are as follows:

A. Ito, indium oxide, weak conductor, the characteristic is that when the thickness drops below 1800 angstroms, it will suddenly become transparent, and the transmittance is 80%. If the thickness is thinner, the transmittance will drop, and it will rise to 80% when the thickness is 300 angstroms. Ito is the main material used in all resistance technology touch screen and capacitance technology touch screen. In fact, the working surface of resistance and capacitance technology touch screen is ITO coating.

B. Nickel gold coating: the outer conductive layer of five wire resistance touch screen uses nickel gold coating material with good ductility. Due to frequent touch of the outer conductive layer, the purpose of using nickel gold material with good ductility is to extend its service life, but the process cost is relatively high. Although nickel gold conductive layer has good ductility, it can only be used as transparent conductor, and is not suitable for working face of resistance touch screen. Because of its high conductivity, and the metal is not easy to achieve very uniform thickness, it is not suitable for voltage distribution layer, but can only be used as probe layer.

Four wire resistance screen

Two transparent metal layers of four wire resistance analog technology work with 5V constant voltage added to each layer: one in vertical direction and one in horizontal direction. A total of four cables are required. Features: high resolution, high speed transport reaction. Surface hardness treatment, reduce scratch, scratch and chemical treatment. With smooth surface and fog surface treatment. Once correction, high stability, never drift.

Five wire resistance screen

The base layer of the five wire resistance technology touch screen adds the voltage fields in two directions to the conductive working surface of the glass through the precise resistance network. We can simply understand that the voltage fields in two directions are added to the same working surface time-sharing, while the outer nickel gold conductive layer is only used as a pure conductor, The position of the touch point can be obtained by detecting the x-axis and y-axis voltage value of the inner ITO contact point after touch.

The five wire resistance touch screen needs four lead wires in the inner layer, and only one conductor in the outer layer. There are five lead wires in the touch screen. Features: high resolution, high speed transport reaction. High surface hardness, reduce scratch, scratch and chemical treatment. 30 million times of contact at the same point can still be used. Conductive glass as the substrate of the medium. Once correction, high stability, never drift. Five wire resistive touch screen has the disadvantages of high price and high environmental requirements.

The limitation of resistance screen

Whether it is a four wire resistive touch screen or a five wire resistive touch screen, they are a completely isolated working environment from the outside world, not afraid of dust and water vapor. It can be touched by any object, and can be used for writing and painting. It is more suitable for the use of limited people in the industrial control field and office. The common disadvantage of resistive touch screen is that the outer layer of the composite film is made of plastic material, and people who don't know how to use too much force or sharp touch may scratch the whole touch screen and lead to scrap. However, within the limit, the scratch will only damage the outer conductive layer. The scratch of the outer conductive layer has nothing to do with the five wire resistive touch screen, but is fatal to the four wire resistive touch screen.

Hangzhou Xuhong Technology Co., Ltd. is a technology-based company of industrial color LCD module, industrial control display products and touch screen control. It is a professional supplier of industrial LCD drive solutions. It is an enterprise unit that carries out display and touch control of terminal equipment through LCD products and display drive solutions. Our long-term stable supply of 3.5 "- 32" industrial LCD screen, TFT LCD screen brand diversification, complete models, can meet different customers under different application environments, medical, vehicle special industry wide temperature, bright, wide angle Industrial LCD screen all stable supply.

The base layer of the five wire resistance technology touch screen adds the voltage fields in two directions to the conductive working surface of the glass through the precise resistance network. We can simply understand that the voltage fields in two directions are added to the same working surface time-sharing, while the outer nickel gold conductive layer is only used as a pure conductor, The position of the touch point can be obtained by detecting the x-axis and y-axis voltage value of the inner ITO contact point after touch.

The five wire resistance touch screen needs four lead wires in the inner layer, and only one conductor in the outer layer. There are five lead wires in the touch screen. Features: high resolution, high speed transport reaction. High surface hardness, reduce scratch, scratch and chemical treatment. 30 million times of contact at the same point can still be used. Conductive glass as the substrate of the medium. Once correction, high stability, never drift. Five wire resistive touch screen has the disadvantages of high price and high environmental requirements.

The limitation of resistance screen

Whether it is a four wire resistive touch screen or a five wire resistive touch screen, they are a completely isolated working environment from the outside world, not afraid of dust and water vapor. It can be touched by any object, and can be used for writing and painting. It is more suitable for the use of limited people in the industrial control field and office. The common disadvantage of resistive touch screen is that the outer layer of the composite film is made of plastic material, and people who don't know how to use too much force or sharp touch may scratch the whole touch screen and lead to scrap. However, within the limit, the scratch will only damage the outer conductive layer. The scratch of the outer conductive layer has nothing to do with the five wire resistive touch screen, but is fatal to the four wire resistive touch screen.

Hangzhou Xuhong Technology Co., Ltd. is a technology-based company of industrial color LCD module, industrial control display products and touch screen control. It is a professional supplier of industrial LCD drive solutions. It is an enterprise unit that carries out display and touch control of terminal equipment through LCD products and display drive solutions. Our long-term stable supply of 3.5 "- 32" industrial LCD screen, TFT LCD screen brand diversification, complete models, can meet different customers under different application environments, medical, vehicle special industry wide temperature, bright, wide angle Industrial LCD screen all stable supply.